-

Get the Most Out of Your RV Battery

Les Schwab is here to help you get the most out of your RV batteries, whether you need to recharge, replace, or you have questions about the best battery setup for your needs. Getting a charge out of your RV and trailer adventures begins and ends with the right battery.

Keeping Your Batteries Charged

During the winter months and long stretches where the battery will not be used, be sure to take your batteries out of your RV or trailer and hook them up to a trickle charger. These small units plug directly into a 110-volt outlet and allow you to keep your batteries fresh and fully charged until you’re ready for your next outdoor adventure.

Les Schwab Tip: It’s a good idea to get your RV and trailer batteries fully charged every year. If your 12-volt battery reaches just 11.2 volts, it’s considered completely discharged. Your local Les Schwab does free battery charging and visual inspections.

12-volt vs. 6-volt

Almost every RV and trailer will come equipped with one or even two 12-volt batteries running in parallel. There’s nothing wrong with this setup. The battery boxes and enclosures are built for those size of batteries. But with a few changes, and a switch to a series of 6-volt batteries, you might get more reserve capacity, which means you can draw power for a longer amount of time between charges.

The benefits of a standard 12-volt battery include the uniformity (your RV or trailer will most often come with 12-volt batteries), cost (12-volt batteries can be less expensive), and simple installation. However, 12-volt batteries may not recharge as quickly as a 6-volt. When it comes to power and longevity, it can take up to three 12-volt batteries running in parallel to match the amp hours in a series of two 6-volt batteries.

Other benefits of running 6-volt batteries in series include a larger amp hour capacity (the amount of time you can use the battery), and a longer battery lifespan. The only real downside is that there may be size differences. 6-volt batteries can sometimes be taller. This can require changes to your battery box or battery storage area.

Les Schwab is Your Battery Expert

Stop by your local Les Schwab before you head out on your first RV or trailer outing of the season. Our team of professionals is here to ensure your batteries are properly charged and installed correctly with our best-in-the-business warranty.

-

10 Tips to Keep Your Older Car Running

How old is the vehicle you drive? According to the Bureau of Transportation Statistics, the average is 12 years. Whether it’s the pandemic and supply chain issues or simply American grit when faced with rising prices and an uncertain future, maintaining a used car makes economic sense. If you’re wondering “how can I maintain my car so it lasts longer,” we have some tips to keep it going strong.

Start With a Free Pre-trip Safety Check

Stop by your local Les Schwab for a free visual inspection of some of your vehicle’s most important safety components. Our pros will tell you what they find and help you get the most life out of your vehicle.

Choose the Right Tires and Wheels

Your tires and wheels are some of the most important parts of your vehicle. To get more life out of your investment, rotate them every 5,000 miles or as recommended. When replacing your tires or wheels on an older vehicle, it can be tempting to cut costs and go cheap. But be sure you’re choosing quality. Your tires will last longer and the right wheels will add to your overall comfort. Plus, they could all be beneficial for your vehicle. Les Schwab can help find the right tires and wheels for your vehicle, budget, and driving needs.

Get Your Alignment Checked

When your vehicle’s tire and wheel assemblies are properly aligned and pointing in the same direction, it can add to the life of your tires, improve fuel efficiency, as well as add comfort and safety to your drive. Les Schwab offers free visual alignment checks. They can take a look at your steering as well. Get yours inspected annually to keep your car or truck safely on the road.

Stay on Top of the Shocks and Struts

As shocks and struts wear out, they can cause your tires, brake pads, and other parts of your vehicle to wear out faster. Properly functioning shocks and struts can help you enjoy a smoother ride and keep your vehicle in contact with the road for added safety and improved control. Les Schwab offers free visual inspections of your shocks and struts.

Keep Up on Your Brakes

Get your brakes checked regularly to ensure these critical safety components are working properly. Routine inspections help lessen the chances of catastrophic brake failure or brake pads wearing to the point that they cause damage to the rotors or other parts of your braking system. If your brakes feel sluggish, unresponsive, or begin making noises, come into Les Schwab. We’ll give them a free visual inspection and help you get safely back on the road.

Check Your Car Battery

Every 12 months, tighten loose battery connections and remove corrosion around the terminals. In addition, summer heat can weaken batteries over time, causing them to die when winter weather returns. At Les Schwab, we do free visual battery inspections to check on the health of your battery.

Change the Oil and Oil Filter Regularly

Want to ruin an engine quickly? Let it run on dirty or a less-than-adequate amount of oil for several months. Forgetting to change the oil and oil filter can lead to engine strain and leaks. Depending on the age of your car or truck, change the oil and filter every 5,000 to 7,000 miles. Les Schwab offers oil changes at some locations.

Have the Timing Belt Inspected

The timing belt (or chain) is one of the most important parts of any vehicle. Hiring a mechanic to replace yours before it breaks can save your engine and a lot of money. Most vehicles need to have their timing belts replaced every 100,000 miles. Check with a qualified engine mechanic or refer to your owner’s manual.

Don’t Trust All Miracle Car Cures

As your car gets older, you may be tempted to try the latest engine-enhancing lubricant or fuel additive. If your mechanic hasn’t told you about it, chances are it’s a gimmick that will cost you money. Or worse, that cure could damage parts of your vehicle.

Replace Other Engine Fluids As Needed

This can include your transmission fluid and differential oil. Check your vehicle owner’s manual for the correct fluid types, how to change them, and when.

Keep Your Radiator Happy

When the radiator is working correctly, nobody notices. But when it starts to struggle, you’ll smell it, see it, and experience it as your car begins to overheat. Every year, flush your radiator and add new coolant to help keep your radiator running strong and properly cool your engine. In addition, replace radiator hoses as needed.

Car Care Starts at Les Schwab

Your local Les Schwab can help prolong the life of your vehicle with expert advice and installations. That includes tires, wheels, batteries, brakes, alignment, as well as shocks and struts. Schedule a time that works for you or stop by.

Important Notice: The information provided above is of a general nature gathered from a variety of resources deemed reasonably reliable. The operation of your vehicle, or the repair or replacement of your vehicle’s equipment, may be different than for a typical vehicle. Please consult your owner’s manual for specific warnings, notices, and other advice relative to the subjects addressed herein.

-

Things to check if you haven’t driven your car for a while:

-

Tire condition and air pressure

-

Signs of fluid leaks under your vehicle

-

Oil, windshield wiper, and coolant fluids

-

Brakes noise as you begin to drive

Resetting the Tire Pressure Light on Your Car

Chances are, you’ve seen your tire pressure light come on if your vehicle has a TPMS (Tire Pressure Monitoring System). The indicator tells you when to inflate your tires or it could be alerting you to a system fault with a light on the dash. Turning that indicator off could be as easy as adjusting the air pressure in your tires, or a bit more complex. Here are some ways to reset that light and how TPMS works.

How to Reset Your Tire Pressure Light When It Comes On

First, you’ll want to check your tire pressure. Don’t forget to check each tire, even your spare. As long as your tires are properly inflated within the specified range for your vehicle, it should reset your tire pressure light.

If the light remains on after adjusting the tire to the proper PSI, you may need to repair your tire, have your TPMS inspected, or try one of the following:

- Go for a 10-minute drive. Get up to 50 MPH, if possible.

- Your vehicle may be equipped with a TPMS reset button or reset procedure in your vehicle control center. Refer to your owner’s manual or consult a professional (highly recommended).

Important note: Resetting the TPMS with a button or your vehicle control center can cause adverse affects if the pressure isn’t set to vehicle specifications.

If those options don’t work, the pros at Les Schwab know the reset procedures to get the job done. We have tools to scan each sensor and program them to your vehicle’s computer system. When your tires are properly inflated or repaired, the indicator light should turn off the next time you start your car or truck, or a few miles down the road.

Why Your Vehicle Has TPMS

TPMS was mandated to help warn drivers of low tire pressure, which can lead to poor fuel economy, sluggish vehicle handling, premature tire wear, increased stopping distances, or even tire failure. Congress passed the TREAD Act in 2000 requiring all vehicles weighing less than 10,000 pounds have tire pressure sensors. Since 2005, most new vehicles have included the system. If you see the TPMS sensor illuminate briefly when you start your car or truck, then you have the system in your vehicle.

While some TPMS use wheel speed sensors linked to your vehicle’s ABS (anti-lock braking system), a majority use small sensors mounted on the inside of each wheel (sometimes including the spare tire). These battery-operated sensors monitor the pressure in the tire and alert you when a tire’s pressure is 25% outside the manufacturer’s recommendation. If you see the tire pressure light on your dash, get to Les Schwab, where we can check the PSI, properly inflate each tire, and check for any other tire or TPMS issues.

What is the Difference Between a TPMS Light and a Tire Pressure Light?

The tire pressure light is just one part of the TPMS system. It is an indicator on your dash that lights up when your tire pressure is low. The TPMS light, available in some vehicles, may light up indicating an issue with the system.

TIRE PRESSURE LIGHT

TPMS SYSTEM LIGHT

Can Cold Weather Cause Your Tire Pressure Light to Go On?

Every winter and summer, TPMS sensors in vehicles throughout the West come to life, telling drivers to check their air pressure. This is normal. Especially in cold weather. When the outside temperatures drop, so does your tire pressure. In the summer, the heat can increase the pressure in your tires.

By regularly checking the pressure in your tires every 30 days, you can avoid these issues. If the light illuminates on an unusually cold morning, don’t worry. It could just be the cold causing the light to come on. To be safe, get the tire pressure checked to avoid any issues. If there has not been a significant change in the weather and your tire pressure light appears, it could mean an air leak or faulty battery in one of your sensors. No matter what causes your TPMS light to turn on, come into any Les Schwab to have it checked out.

What Does It Mean If the TPMS Light Is Flashing or Illuminates

There can be many causes for a flashing TPMS light, but the most common reason could be that your system needs to be reset. Or, there could be other issues with a sensor, such as a dead battery, or the TPMS unit itself. The pros at Les Schwab can do a quick diagnostic and pinpoint the issue.

Les Schwab is Your Tire Pressure Headquarters

Proper air pressure is one of the most important parts of any tire. Pull into your local Les Schwab and we’ll check your tire pressure, add air when needed, and reset your TPMS light and get you safely back on the road.

How to Take Your Car Out of Winter Storage Checklist

-

Check the battery charge. Make sure battery terminal connections are snug and there’s no corrosion.

-

Inspect wiring and hoses. Check for rodent damage, cracks and loose connections.

-

Make sure your oil level is normal. Get an oil change as soon as possible.

-

Top off air in tires and make sure the tread is intact (no bulges, cracks or balding areas).

-

Look under the vehicle for signs of fluid leaks.

-

Have brake pads and shocks examined.

-

Verify that headlights, brights, taillights and blinkers are operating.

-

Clear the exhaust pipe, if you plugged it to keep out mice.

-

Air out the interior.

Learn MoreHow to Tell If Your Shocks or Struts Are Bad

It’s hard to know when to replace shocks and struts. These hard-to-inspect parts often go bad so slowly that you might not notice the reduced ride comfort and road control. Plus, there’s no set time or mileage when aging shocks or struts are due for replacement. Thankfully, there are ways to know when it might be time to get your shocks and struts checked at Les Schwab.

What Are Shocks and Struts?

Every car and truck is suspended by a combination of springs, shocks, and struts. If you look behind any of your four wheels, you’ll see these hard-working parts that move up and down, up to 1,900 times every mile. By the time you put 50,000 miles on your vehicle, your shocks and struts will have done their job 75-million times, working in tandem with your brakes, steering, suspension, tires, and your modern crash-avoidance systems to keep you in control and traveling safely on the road.

What Do Shocks and Struts Do?

Shocks and struts in good condition help your car handle bumps, debris, sudden stops, swerving, potholes, wind gusts or sharp turns. They control the side-to-side, front-to-back and up-and-down shifts of the car’s weight to keep your tires in contact with the road and you in control of your vehicle.

They also:

- Maintain your tire’s contact with the road.

- Prevent your tires and wheels from moving up and down too much.

- Contribute to stability as you accelerate, stop and turn.

- Add to ride comfort by absorbing jolts and bumpiness from irregular road surfaces.

- Help control a vehicle’s body movement (side-to-side roll, bouncing).

- Promote even wear for longer tire life.

Contrary to popular belief, shocks and struts do not typically support your vehicle’s weight or any loads your truck or vehicle might be carrying. The springs do that job. However, worn-out shocks and struts put more strain on the springs as well as other essential suspension parts. Without the control that a good shock or strut provides, these other parts get overworked, causing fatigue and premature wear.

Signs Your Shocks or Struts Are Worn

Properly working shocks and struts add to your safety on the road and help reduce damage to other parts of your vehicle. Look for these signs that indicate it might be time to get your shocks and struts checked and replaced.

Unusual tire wear (including cupping). If you spot cupping (as seen in the image below) or other unusual tire wear you may have issues with your shocks or struts, which is throwing off your alignment. This can be especially important to notice if a rotation was performed but abnormal wear is still occurring.

Cupping is uneven tire wear that looks like hollowed out areas on the tread. Rubber shock covers that are cracking, peeling or off-center. These covers can be found at the top and bottom of the shocks.

Leaking fluid. If you find clear or light brown fluid on the outside of the shocks or struts, it could indicate a broken seal.

Ride issues. If your vehicle dives when braking, bottoms out (scrapes loudly) when going over a speed bump, the rear-end squats when accelerating, or your vehicle bounces more than usual after going over a bump, it could be signs of bad shocks or struts.

Braking issues. You might notice that your vehicle takes longer to stop than usual.

Swaying. This can be especially noticeable after a turn, lane change, or in cross winds.

Unusual noises. As the shocks or struts wear, they can fail to do their job. This can cause many different sounds, including knocking and banging.

See our shock and strut service repair FAQs.

What Will Happen If I Drive on Worn or Damaged Shocks and Struts

It’s important to maintain contact with the road, especially when going over bumps or keeping up with highway traffic. Your vehicle’s suspension system, including shocks and/or struts, is great at that job when every part is working properly.

Over time, those parts will wear out. You might not even notice as it gradually degrades. When they’re not working properly, it can reduce your control and safety. It can also cause added wear to other parts of your vehicle, including your tires.

Replacing worn parts before they get bad can help keep your vehicle’s electronic systems and suspension working properly, extending your vehicle’s life — and keeping you safer on the road.

Shocks and Struts Aren’t Just About a Smooth Ride

Today’s vehicles have highly engineered electronic safety systems (vehicle stability systems, ABS (anti-lock brakes), traction control, collision prevention control and automated braking). These all work together to keep tires in proper contact with the road and provide the most stability.

When you have an unexpected hard stop or swerve, your vehicle’s crash avoidance systems send instant electronic signals to the brakes and other critical components. If ride control parts like shocks and struts are worn, they might not properly respond. Additionally, stopping distances might increase and brakes and tires could wear more quickly. Plus, there could be added strain on the springs.

How Long Do They Last (When Should I Replace Them)?

That all depends on the amount of wear and tear the shocks and struts get, the quality of roads you drive, if you haul heavy loads, and how aggressive you are behind the wheel. That’s why periodic inspections are important.

Get yours checked annually (or 12,000 miles) with every alignment, tire rotation, if you feel any ride-control issues, or anytime you buy new tires.

Les Schwab Can Help

We’re your suspension inspection experts. Our service professionals know what to look for and how to get your car or truck back to its original control and handling. Stop by or schedule an appointment today.

Lowering Suspension: Pros and Cons

Lowering your car or truck so it’s closer to the ground is a popular way to customize your ride. Done right, it’s a great look that also boosts handling performance. Done wrong, it could compromise handling, drivability and traction, reduce tire tread life and even damage parts.

Pluses and Minuses of Lowering Suspension

PROS CONS More road feel Reduced ride comfort Stiffer ride Impractical for rough roads Less roll when cornering Accelerated or uneven tire wear Better handling Chance of bottoming out Improved aerodynamics Potential rubbing on parts or tires Improved traction Can’t use a standard jack Less rollover risk Cost Great looks Warranty issues

Benefits

More Road Feel

A lowered suspension helps a driver be highly attuned to how their vehicle acts on different pavement as more of the vibrations from imperfections in the road surface come through the steering wheel.Stiffer Ride

With this setup, you have to have more rigid springs so the front or back of your vehicle won’t bottom out over bumps or depressions. This is the driving experience many prefer, versus a cushier ride from, say, a luxury sedan.Less Lean in Corners

The lean of a vehicle around a sharp turn is greatly reduced because the shift of weight is less due to the lower center of gravity. The part of the vehicle on the outside of a turn stays more level with the inside. This lets a car settle more quickly into a turn and act more responsively.Better Handling

Another effect of being closer to the ground is improved responsiveness, more stability, and grip at speed. Because lowering means getting stiffer springs, there is less weight transfer when you hit the gas or brake hard. This means you’ll enjoy faster acceleration and quicker stops.Less Air Drag

Lowered vehicles are more aerodynamic. There’s less air hitting the wheels and tires (that are not streamlined shapes). This makes these cars faster. Some owners of low-stance vehicles also notice improved gas mileage. BUT, lowering a car too much will actually increase wind drag.Less Rollover Risk

Lowered vehicles have a lower center of gravity, which decreases rollover risk when cornering.Improved Traction

Lowering generally means you’ll put a plus-sized tire and wheel package on the vehicle. Such tires have shorter sidewalls, a larger contact patch (that keeps more rubber in contact with the road) and less roll around corners.Good Looks

Cars and trucks that have been lowered with custom wheels are attention-getters. It’s a more aggressive and performance-oriented look that stands out in a crowd.

Drawbacks

Less Ride Comfort

If you and your passengers are accustomed to a softer suspension that cushions impacts like bumps and potholes, you may think less of the ride comfort of a lower suspension. You may also notice increased road noise since you’re closer to the pavement.No Go on Rough Roads

The lower clearance will not be your friend on rutted, rocky, washboard and potholed roads.Uneven or Accelerated Tire Wear

Lowering changes the geometry of your wheel-tire fitment. If it’s done improperly, your car may have an alignment problem that results in premature or extreme wear patterns.Bottoming Out

Even an inch-and-a-half lower suspension can cause problems around corners, with slight potholes or on speed bumps. Traveling over the lip of a parking garage or starting up a driveway or ramp could cause the front of your vehicle to hit the pavement. Contact with the ground can cause serious damage to components underneath the car, like the exhaust system and oil pan.If you ever need a tow truck, you may require a flat bed. Otherwise, there could be a problem with the back body of the vehicle dragging on the ground.

Potential Rubbing on Parts or Tires

Poorly done or extreme lowering can cause suspension and steering parts to contact each other, the wheels or the tires. It could also cause tires to rub the body during turns or going over bumps.Can’t Use a Standard Jack

If you get a flat tire, you may find out at an inconvenient time that there’s not enough clearance to get the unit under the vehicle’s frame.Cost

Quality components and keeping correct alignment can get pricey. The lower you go, the more chance you’ll need additional parts. For example, if coilovers (meaning coil spring over shock) are part of your new setup, you’re likely looking at an outlay of $1,000 or more.Warranty Issues

You should check both your owner’s manual and any manufacturer’s or aftermarket warranty to determine if 1) the manufacturer advises against lowering your car, or 2) if lowering your car will void or adversely affect any warranty coverage you currently have.

Know This Before You Modify Your Suspension

Here’s what to know before you go low.

- If it’s higher performance you’re after, you may need to lower a lot less than you think. It’s easy to miss the mark and actually make your suspension worse. To be sure that components like struts and springs can do the work of keeping tires at the right angles, get expert help.

- Don’t cut corners when it comes to shocks, struts or other components. You’re making changes to the structure and balance of your vehicle. You don’t want to risk failing parts.

- If you modify your vehicle in ways that aren’t road legal, your insurer may not pay a claim for damage. Talk to your agent before you customize your ride and ask if your premiums will go up or policy terms change.

- Installing extreme aftermarket wheel-tire setups or suspension changes can result in steering, suspension or drivetrain problems that won’t be covered by your vehicle warranty. Check to see if the modifications you’re planning will result in denied warranty claims BEFORE installation.

- Get an alignment after you lower to ensure the best handling and tire life.

- Take care while you get accustomed to how your new setup performs. With the much stiffer suspension, your vehicle may steer a little differently and won’t absorb road shocks as well. A sudden hard brake or tight turn on a bumpy road could cause a loss of traction.

Any time you change your vehicle’s OE (original equipment) suspension, you should be sure that you’re not creating a setup that is either unsafe or is going to cause problems with other car functions. Like with many aftermarket customizations, it’s about finding the right balance of safety, performance, looks, cost, and drivability. Stop by your local Les Schwab for help.

Schedule an Appointment

Post-Winter Car & Tire Maintenance Checklist

-

Change out your winter tires.

If you haven’t already, change from your winter tires to a set of all-season or summer tires. You’ll get more life out of your winter tires next season and you’ll add safety to your warm-weather trips.

-

Get an alignment.

Why? Because when your tires and wheels are properly aligned, you’ll get more miles per gallon (or range), and your tires will last longer. While you’re at it, get your tires rebalanced.

-

Get your battery checked.

Time and weather will wear down your car’s battery. Instead of finding yourself stranded, get to Les Schwab and have yours checked out. If you need a new one, our pros will take care of the installation.

-

Check your tire tread and air pressure.

Use the penny test to determine how much tread you have left on your tires. Or stop by Les Schwab and we’ll check them for free. We’ll even top off the air pressure on all four tires, including the spare if you request it.

-

Get your tires rotated.

This quick chore can help spot uneven tire wear early, saving you money. At Les Schwab, we’ll rotate your tires for free when you buy them from us.

-

Change your oil and other fluids.

Don’t have time or the space to change yours? Some Les Schwab locations offer oil changes. Schedule your appointment today.

-

Replace wiper blades.

The winter months will chew away at the rubber on those blades. Now is a good time to replace them, before you’re caught in a rainstorm with streaky windows. Don’t forget to add wiper fluid. Your local Les Schwab carries and can install your next set of wiper blades.

-

Clean your headlight covers.

While you’re at it, replace the low and high beams if they are burned out or haven’t been changed in a while.

-

Check your indicators.

With one person outside the vehicle and another behind the driver’s seat, check the brake lights, backup lights, as well as turn signals in the front and rear.

-

Get your brakes checked.

Among the most important parts of your vehicle are your brakes. If they’re starting to make noises, grab, pulse, or feel soft when you hit the pedal, it might be time to head into Les Schwab for a free visual inspection and professional recommendations.

Why We Replace Calipers With Your Brake Service

Your brakes always get a workout, whether you’re picking up the kids from practice or heading out into the hills. Every time you press on that brake pedal or your vehicle’s traction control, stability control, or crash avoidance systems are activated, a host of hydraulics and mechanisms work in unison to bring your vehicle to a solid stop.

Because of this, when brakes are worn out, you want to replace more than just the worn-out brake pads. Here’s why.

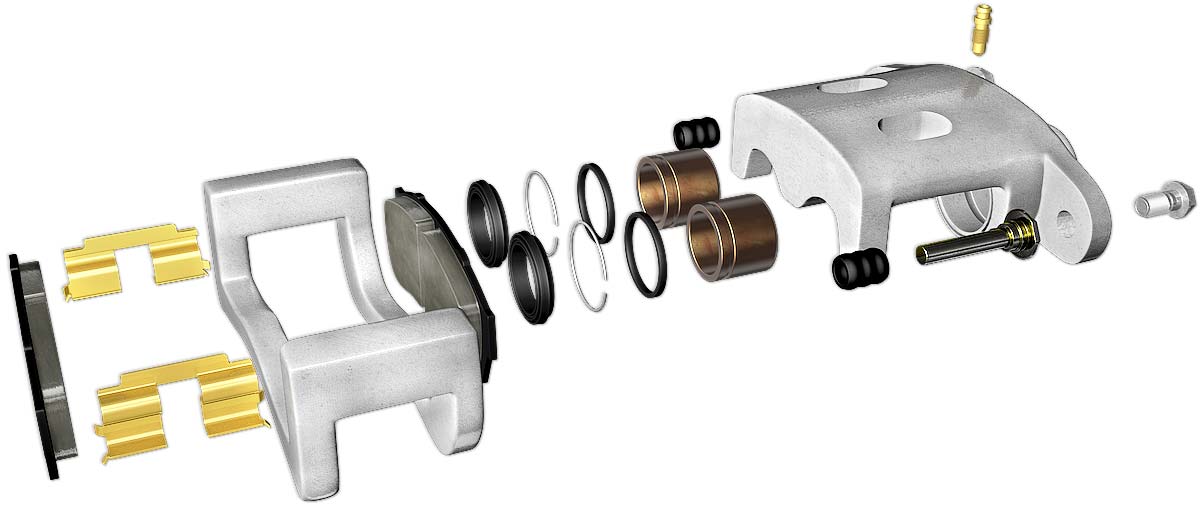

Calipers Make Your Brakes Work

Yes, there are a lot of other moving parts that go into your braking system, but the calipers provide the clamping force that make it all happen. They take the pressure from your brake pedal and apply it to your brake pads. That, in turn, causes the friction to slow down your vehicle.

Les Schwab Tip: Learn more about brake types in our Complete Guide to Disc Brakes and Drum Brakes.

Sure, a new set of brake pads give you a quick fix to worn brakes. But, we’ve learned over the last 30+ years and thousands of brake repairs that replacing just the pads often leads to other braking issues, such as brake pedal pulsations, brake squeaking or squealing, or worn rubber seals. All of this can cause uneven or faster wear of your brake pads over time.

Built-up grime on your caliper pistons and slides, which become more exposed as your brake pads are wearing thin, can cause caliper malfunction if not addressed when pads are replaced. This short video demonstrates what happens when only the brake pads are replaced and the caliper pistons are forced back into the bore.

The Important Details

Calipers include a handful of parts, including the pistons, piston seals, caliper hardware, and dust boots. To work, all the moving parts in the caliper need to be clean and smooth. Here’s the role that each plays in stopping your vehicle.

- Piston seals flex as the piston moves out. They pull the piston back into the caliper housing. This small part can cause a lot of big issues if they’re not replaced with the brake pads.

- Dust boots protect the caliper from debris and other road grime and dirt. As they get older, dust boots will deteriorate, allowing this grime into the caliper, piston and seal.

- Caliper hardware needs to allow the caliper to float and slide. If the hardware gets rusted or corroded, the pieces can’t perform as well as they should.

Get Complete Brake Service at Les Schwab

Corners aren’t something you want to cut when you’re talking about brakes. When we replace your brakes, you get complete service. This includes premium quality brake pads and remanufactured brake calipers that are as good as the those your vehicle had when it was new.

Remanufactured calipers come with new seals and dust boots, bleeder screws, and hardware, which have been thoroughly cleaned and inspected for quality, performance, and safety.

Bottom line, your car will stop when you hit the brakes. And that’s something we can all appreciate.

Les Schwab Tip: Understand the ins and outs of brake repairs with our Brake Servicing 101: Advice on Making Sure It Gets Done Right.

Schedule an AppointmentWinter Driving Tips: Winterize Your Vehicle

Like unpacking your heavy winter clothes that got boxed up in the spring, winterizing your car is a quick and easy process that can make any trip or commute a lot less stressful. Here’s what you need to know.

- Check your battery. A good battery is one of the unsung heroes of your daily commute. When it fails, everything comes to a screeching halt. Check your battery condition and ensure it’s still holding a charge before you need it this winter.

- Winterize your ride. This guide from Consumer Reports shares all the tools you’ll need to get your vehicle ready for the cold months ahead.

- Be ready for any weather. Winter driving conditions are rarely ideal, so it makes sense to give yourself extra time whether you’re driving across town or across the state. Also, be sure to keep the tank full, or nearly full, just in case you get stuck in a winter storm that takes hours to maneuver.

Get More Winter Driving TipsThe Basics of Road-Force Balancing

No wheel and tire assembly is ever perfect, and vibrations can happen. A road-force balance machine uses a load-roller to simulate road pressure as an efficient way to identify even the slightest inconsistencies. This, in turn, easily provides a technician with a diagnosis of those variations in the tire and wheel assembly, allowing them to make adjustments that mitigate any vibration issues.

Here’s how it all works.

Balance Sometimes Requires More Precision

Even when you buy four new wheels or four new tires, there will be small differences in their weight, stiffness, and balance. Low and high points in the wheel and tire construction are called lateral runout or radial runout. Stiff spots on the tire are referred to as force variation.

What does this mean to you? It means no two tires or wheels are exactly alike. When new tires are installed or standard balancing has not remedied an issue, a road-force balance machine can be used to counteract unresolved runouts or variations by identifying what a technician needs to properly balance your wheel and tire assembly.

How does this machine work? Once a hood closes on the road-force balancer, the wheel and tire assembly begins to spin. A second diagnostic wheel or load-roller pushes against the tire to test and record its balance as if it were on the road.

That test tells a technician where inconsistencies can be found and how to properly balance the wheel and tire assembly. Fixes can involve adding weights to the wheel, remounting the tire to find a better match, and bead massaging to push the new tire into the rim for a better fit.

Equalizing Your Custom Wheels

Today’s vehicles come with some impressive wheel sizes. Plus, you can add custom wheels for an enhanced design and look. But with bigger wheels come shorter tire sidewalls, which can be more sensitive to road vibration forces. A road-force balance can help alleviate those issues.

Find Balance at Les Schwab

Keep in mind, some vibrations cannot be resolved by any type of balancing. These include, but are not limited to, a bent rim, irregular tire wear, wheel and tire defects, and other mechanical issues with your vehicle.

However, if you’re experiencing a vibration, the pros at Les Schwab have the technology and knowhow to pinpoint the cause. Stop by or schedule a free, pre-trip safety check. Our pros will give your vehicle a quick inspection and show you all the options.

Quick Tips to Start Your Overlanding Journey

Overlanding got its start in the Australian outback as a way to journey into the wilderness while always having everything a person needs to survive. Fast forward to today, and Overlanding has become something of a personal statement. When your vehicle is modified for an overland adventure, it stands out with an extra bold stance and added clearance to accommodate beefier tires.

Here are some quick tips to get your vehicle ready for an overland journey.

Start With the Vehicle

Overlanding is all about the journey. But it’s hard to enjoy that journey in the wrong vehicle. Popular options that can easily be raised a few inches include light trucks and SUVs like the Toyota 4-Runner and crossovers such as the Subaru Crosstrek.

Image courtesy of Black Rhino Wheels

Give Yourself Some Clearance

Even adding just two inches to your vehicle’s suspension can make a big difference. Of course, people will notice as you drive around town. But more importantly, you’ll be better prepared for off-roading and outfitting your vehicle with the remaining necessities, including gear, food, and a roof-top tent.

At Les Schwab, we have suspension lift kits in stock for most vehicles. When we install it, we’ll double-check the suspension, brakes, shocks, steering, and alignment. You know, the important stuff. We’ll even perform a retorque and check the alignment to ensure your lift is done right.

Do You Need Bigger Wheels and Tires?

Once you’ve lifted your vehicle a couple of inches, you can choose to keep the same height tires on the vehicle. However, you could be missing out on some added clearance and traction. Upgrading to a bigger wheel and tire package will allow you to choose beefier off-road tires for your vehicle, which are designed for taking you off the beaten path.

Off-road tires typically have larger voids between the tread blocks. Those voids allow the tires to dig into dirt, sand, and rocks, giving you more traction. Plus, the thicker tread blocks in off-road tires can better withstand cuts and punctures.

Les Schwab Tip: We can help you pick the right combination of off-road and highway capabilities to meet your needs.

Items You’ll Need

Once you’re ready for an overland adventure, you’ll want to outfit your vehicle with all the necessities. This includes a tire-patch kit and air compressor, a spare tire that is mounted to the top or back of your vehicle, a jack, plenty of food and prep tools, water, a roof rack, and possibly a roof tent.

Why a roof tent? These popular options allow for easy set up after a long day of driving off-road. Plus, they don’t take up precious cargo space on the inside of your vehicle, where you’ll be storing food, sleeping bags, and clothes. You could also bring along extra flashlights, a portable generator, and a first-aid kit.

Les Schwab Tip: As with any outdoor adventure, always pack out what you pack in...and more.

Get Your Overland Lift Done Right

The pros at Les Schwab have been lifting trucks, crossovers, and SUVs for years. Stop by today and we’ll show you all of your options, including the perfect wheel and tire packages for added style and off-road attitude.

Schedule an AppointmentThe Real Reasons Your Car Battery Keeps Dying

Modern car batteries are designed to start your car or truck, run all of the electronics, and maintain the vehicle’s computer memory. But over time, batteries do eventually run out of juice — sometimes way before their time. Here are the real reasons your car battery dies, or keeps dying, and what you can do to get the most out of it.

Les Schwab Tip: If your battery seems to die while you’re driving, it could be an issue with your vehicle’s electrical components or charging system. You might need to visit your mechanic or stop by Les Schwab so we can double-check your battery and connections.

Why Your Car Battery Keeps Dying

While car batteries slowly die over time, high heat, brutal cold, excessive use of vehicle accessories (after-market equipment), and other mechanical issues can shorten the life of even the toughest battery. Read How Your Battery Works to understand why batteries die over time. The top six reasons batteries die include:

Lights left on. That can be your car headlights, dome light, light in the glove box, or trunk light. Even vanity mirror lights can drain a battery if left on overnight.

Parasitic draw. Your car battery can drain over time from stereo components (subwoofers), phone chargers, and anything you leave plugged into vehicle outlets that continue to draw power from the battery after the car is turned off. Other power drains include interior and below-vehicle LED lights.

Loose or corroded connections. A loose connection can damage the battery and/or drain it. Check your battery cables often for corrosion. If you find any, clean it off to ensure a tight connection.

Excessive heat and cold. It seems like batteries die most often in the winter. You go to start your car, and the battery just cannot turn the engine over. But it’s not the cold that kills most batteries. Hot summer months can deteriorate your battery. Then, you notice that lack of power in the winter. To help avoid damage to your battery from heat, park your vehicle in a garage or under a shelter on hot summer days.

The alternator has issues. Once your car is started, the alternator helps it stay charged. But if the alternator is going bad or the alternator belt is slipping, it might not recharge your battery.

Quick trips or leaving your car parked too long. Too many quick trips (less than 15 minutes in length) can degrade a battery. Additionally, letting a car sit for too long without being started (weeks or months) can cause issues.

Age. Batteries don’t last forever. How often you start your vehicle, how far you drive, the health of your alternator, the hot and cold conditions in your region, and more can affect the lifespan of your battery.

How to Prevent Your Battery From Draining, and What Causes It

The life of your car battery depends on where you live, how much you drive, and more. If your car needs a new battery, Les Schwab is here to help with batteries for everything you drive. Here are a few tips to help keep your battery from draining.

Unplug Extra Accessories: Known as parasitic draw, your car battery can drain from stereo components and phone chargers that continue to work when the car is turned off. Also, be on the lookout for glove-box lights, trunk lights, and interior lights that remain illuminated.

Take a 15-minute drive: At least once per week, take your car for a short drive. As long as your alternator is working correctly, this will help maintain the battery state of charge.

Don’t leave your headlights on: Turn the switch to the “off” position, even if your lights go off automatically.

Avoid deep discharging: Don’t leave the lights on or the stereo going while the car is turned off. This can result in a dead battery.

Tighten and Clean Battery Connections: If your battery terminals are loose or corroded, they can drain or damage the battery. It could also cause your car to stall. If you do find corrosion, it’s easy to clean with a stiff-bristle brush (an old toothbrush works great), and a mixture of one part baking soda to three parts water. With a little elbow grease, the corrosion will vanish. Just be careful not to get any of the baking soda/water mixture in your battery or on other parts of your engine or vehicle.

What to Do When Your Battery Dies

Dead batteries happen to everyone. It can be frustrating, especially when you’re late for work. Having a set of jumper cables or a jump starter can get you going again. We’ve put together a jump-start how-to video to help get your car or truck started.

When you’re a Les Schwab customer, you’re welcome to call us during regular business hours. If we’re available, we may be able to drive to your location and give you a jump start.

Need More Help? Give Us a Visit!

Les Schwab gets a charge out of checking your battery. Come on by and we’ll perform a free inspection. Whether it just needs to be recharged or if you need a new battery, we can help, including new batteries for most vehicles.

Need a New Battery? Start Here.

If you’re wondering how often you should change your car battery, how long it takes to change a battery, or why your battery died suddenly without warning, the answer might not be what you’re expecting.

Leaving Battery Installation to the Professionals

At one time, removing your vehicle’s old, dead battery and installing a new one was an easy bit of car maintenance. Today’s vehicles are more complex. And, so are today’s automotive batteries. Vehicles from the mid-90s may require special equipment and care when changing a new battery. In fact, don’t be surprised if you’re not sure how to even unhook your car battery.

The reason for that complexity? Most of today’s cars and trucks are packed with computers and other special electronic equipment that rely on a continuous power supply. Incorrectly changing out a battery can affect your radio presets, security system, power windows, as well as your air conditioning and heating controls.

More importantly, a loss of power during battery installation can also cause unseen issues to your vehicle’s operating systems. Because today’s automotive computers adapt while you drive, a loss of power can negatively affect systems that regulate your transmission, engine efficiency, and battery charging.

Batteries aren’t always under the hood of today’s vehicles. They may be located on the inside of your vehicle, which require a specific battery that needs ventilation to keep harmful gasses out of your vehicle’s interior.

Start at Les Schwab

If you think you have a drained battery, head over to a Les Schwab near you. Our battery installation teams use the latest equipment to maintain power to those sensitive systems during the battery installation process. We also use the latest in diagnostics and testing equipment to check the overall health of your battery, charging and starting systems.

Know the Nearly Dead Battery Warning Signs

It doesn’t take a lot of power to start today’s vehicles, which means you might not get the telltale slow-start associated with a dying battery. You might not even notice your battery is going dead until it’s too late.

Things that can contribute to a drained battery include extreme hot and cold weather, how often and far you drive each day, how long your vehicle is parked in one location without being started, and if you have any aftermarket equipment installed such as a stereo or auxiliary electronics and lighting. See our article How Your Auto Battery Works to understand why batteries die over time and how a car battery recharges.

LesSchwab Tip: Because the signs of a weak battery might not be as noticeable and batteries rarely die at a convenient time, the professionals at your local Les Schwab can check your battery condition for free — even if it isn’t dead.

While it’s common to experience a dead battery in the winter, it’s actually the hot, summer months that cause most battery wear and tear. This is due to an increase in the chemical reactions inside the battery during hot days. When the weather gets cold, that damage is more likely to cause battery failure.

Enjoy up to a Seven Year Battery Warranty

Get a jump on your next battery at your local Les Schwab. We carry automotive batteries for cars, pickup trucks, SUVs, crossovers, RVs, and more. We’ll help you find the best battery for your vehicle and get you quickly back on the road. Our professional installation takes the guesswork and worry out of buying a new battery. Learn more at Les Schwab Tire Centers.

8 Signs You Could Have Brake Problems

Car brake repair and brake servicing are important parts of proper vehicle maintenance. When you take care of your brakes, they’ll take care of you when you need them most. However, even with regular maintenance, the brakes on your vehicle may require a professional inspection and servicing if you encounter one or more of these eight brake problem warning signs and symptoms.

1. Brake Light On

If a brake light indicator appears on your dashboard, it’s either time for your regular maintenance or it’s an alert to a potential problem. These are some of the more common dashboard alerts that appear in today’s vehicles. Note: Consult your vehicle owner’s manual for possible causes for these and other indicators.

Brake Pad Indicator

This light lets you know your brake pads may be wearing out, along with other non-visible reasons. Either way, get them inspected at Les Schwab.

Brake Fluid Level Indicator

This light will flash when your brake fluid levels are low. You may be able to top off the fluid to keep your brakes functioning properly, or stop by your local Les Schwab and we’ll give you a hand.

Parking Brake Indicator

When this light appears, your parking brake is either engaged or there is a problem with it. To diagnose the possible issue, engage and disengage your parking brake. If the indicator goes away, there are no issues. If it still won’t go away, come to Les Schwab.

Les Schwab Tip: see our post about dashboard lights to understand the most common vehicle alerts.

2. Squealing or Squeaking Noises

Odd or unusual noises coming from your brakes aren’t always a sign of problems. It could just be a foreign object lodged in your brakes (a pebble or debris). It could also be your brake-pad wear indicators. These bits of metal in your brake pad come in contact with the rotor to emit a high-pitched noise when you apply the brakes. This lets you know it’s time to get your brake pads replaced.

3. Grinding Noises

Grinding noises, whether you have disc or drum brakes, could mean your brakes need servicing right away. In some cases, the sounds may be the brake pad or shoe scraping on metal contact points. A trip to Les Schwab is recommended when you hear or feel any form of brake grinding.

4. Wobbling, Vibrating, or Pulsing When Braking

If your steering wheel or vehicle shakes, vibrates, or pulses when you apply the brakes, it could be an uneven rotor. Brake rotors, which are a vital part of your disc brakes, are large metal discs attached to both ends of your vehicle’s axle. When you hit the brakes, the brake pads push against the rotors, which stops your wheels from spinning.

Wobbling, vibrating, or pulsing can occur if the rotor surface area is not flat (has uneven areas). Over time, it’s normal for the rotor surface to wear down and possibly become uneven. Braking friction, when you apply the brakes, results in the transfer of pad material to the rotor surface. If the pad material transfers unevenly, you may experience vibration when braking. Left uneven, the material will continue to accumulate, worsening over time. During brake servicing, the face of the rotor should be smoothed or evened out to correct flaws and keep you from feeling a wobble when you brake. If the rotors are too far worn to be serviced, they will need to be replaced.

5. Leaking Fluid

When you apply your brakes, a lot of things happen all at once. An important part of the process involves brake fluid. This is used to create hydraulic pressure, which pushes the brake pad against the rotor (the large metal disc attached to the end of your axle). If your vehicle has no brake fluid, you won’t be able to stop safely. Check your vehicle’s brake fluid often. Not sure how? Stop by Les Schwab and we’ll be glad to help.

6. Spongy or Soft Brakes

When you press on the brakes, you want to feel some resistance. If they feel soft or the pedal goes all the way to the floorboard, it could indicate air or moisture in the braking system. It could also be a problem with the master cylinder, which is often located in the engine compartment near the brake pedal. This cylinder is where the whole braking system starts. If the master cylinder is malfunctioning, the pressure you apply to the brakes won’t activate the calipers to then press the pads against the rotors. In other words, you might not stop when needed. If you notice spongy or soft brakes, get to Les Schwab.

7. Car Pulling to One Side When Braking

While this could be caused by any number of vehicle issues, it could be your brakes. When this happens on the front brakes, one brake may be working while another is not. This causes pull in the direction of the side that is creating braking force (still working). If only one rear caliper is not working properly, it can go unnoticed. Get your brakes inspected regularly at Les Schwab to spot these issues before they become a problem.

8. Burning Smells

A sharp, chemical odor could be a sign of overheated brakes. To avoid brake failure, pull over to a safe place and allow the brakes to cool. Double-check that the parking brake is off. If there’s any smoke coming from a wheel, it may be that the brake caliper is malfunctioning and locked in place. In this case, it may be unsafe to continue driving without immediate repairs.

What Happens If You Drive With Bad Brakes?

Driving with bad or worn brakes can be dangerous for you and your family — especially if those brakes fail to stop your vehicle when necessary. If you experience any of these 8 brake problems or warning signs, get them inspected and serviced immediately. Don’t wait. Your safety is riding on them. Stop by Les Schwab for a free visual brake inspection and recommendations to get your brakes in tip-top shape.

How Do I Know If I Really Need New Brakes?

There are a lot of moving parts and special fluids to consider when diagnosing your brakes. When dust and small rocks get into your braking system, you’ll hear some concerning squealing. Thankfully, that issue is easy to fix. Other problems require immediate repairs. We have some tips to help you decide if you really need brake servicing. If you’re still not sure, stop by Les Schwab and our pros will take a look.

How To Extend The Life Of Your Brakes?

Getting the most out of your brakes can add safety to every outing and save you money. Tips include carefully watching traffic to avoid stomping hard on the brakes, planning ahead when driving in the snow and rain so you’re not constantly applying brake pressure, as well as other smart driving tips to prolong the life of your pads and rotors. Check out these three essential tips.

Les Schwab Knows Brakes and Safety

The more you drive, the quicker your brake parts will wear out. Delaying needed services could put you at risk. Anytime you experience braking problems or want to have your brakes professionally checked, get to your local Les Schwab. Our pros understand how every part of your braking system works together for your safety. Schedule your appointment, or just stop by and we’ll help you get safely back on the road.

15 Tips for Better Gas Mileage and Range

Gas prices are always just a little higher than we’d like. And getting an electric vehicle’s battery fully charged isn’t free and takes time. So, it makes sense to find ways to get more out of every gallon and kilo-watt hour. Careful driving and some regularly scheduled auto maintenance can help you maximize your MPG (miles per gallon) and range. The professionals at Les Schwab have put together 15 tips to help boost your vehicle’s fuel and range efficiency, whether you drive a gas- or diesel-powered truck, an electric car, or a hybrid.

1. Maintain Proper Tire Pressure

Under-inflated tires can reduce your MPG and range. A lack of air pressure can also affect handling, stopping power, and impact-crash avoidance systems, according to the National Highway Traffic Safety Administration (NHTSA). Over time, it can also damage your tires. To help prevent these issues and improve your MPG and range, stop by Les Schwab for a free monthly air check.

2. Use Low-Rolling-Resistance Tires

When buying new tires, consider low-rolling-resistance options. These tires, which may be an option for your vehicle, are specifically engineered to enhance fuel efficiency and range by minimizing friction between the tires and the road. While they are not ideal for winter conditions, these innovative tires can help you save on gas and boost range by striking a balance between what you need for safety and what you need to save money.

3. Align and Rotate Your Tires Regularly

Proper alignment and tire rotations done at regular intervals can reduce rolling resistance and improve your MPG and range. Tire rotations should be done every 5,000 miles or with every oil change to get the most life out of your tires as possible. Additionally, vehicle alignments are part of basic auto maintenance, whether you drive a gas- or battery-powered car or truck. Get your vehicle alignment checked at Les Schwab once a year.

4. Avoid In-City Driving

While electric vehicles get far better range in the city than on the highway, gas- or diesel-powered vehicles in stop-and-go traffic can see a serious decrease in MPG — often by up to 50%, according to the U.S. Department of Energy. The key to increasing your MPG is to maintain a constant speed. Driving on the highway can maximize fuel efficiency for many vehicles. Whenever possible, take highways or routes with fewer stops to maintain a steady speed.

5. Plan Your Trips

Combine errands into a single trip and avoid unnecessary backtracking. This can significantly cut down on the number of miles you drive. By carefully planning your routes, you can maximize your MPG with fewer stops, conserve fuel, save time, and reduce wear and tear on your vehicle. These small adjustments can help boost gas mileage and overall range.

6. Drive Sensibly

Accelerate, turn, and brake gradually as if there is a very full pot of chili in the passenger seat (seat belted in, of course). In other words, be gentle. Slow, steady acceleration and non-aggressive driving can improve your MPG and range.

According to the U.S. Department of Energy, aggressive driving, including speeding and hard braking, can lower MPG on gas-powered vehicles by 15–30% on highways and 10–40% in stop-and-go traffic. The good news is driving at or near posted speed limits can help maintain fuel efficiency and battery range. Additionally, anticipate traffic stops and other slowdowns as much as possible. This might include coasting to a stop. If you drive an electric vehicle, apply gentle pressure to the brakes to achieve maximum regenerative power.

7. Pay Attention to Your Brakes for Drag

Periodically, get your brakes inspected to ensure they’re functioning correctly and not causing unnecessary resistance. That’s because you can experience a reduction in fuel and battery efficiency if your brakes are constantly rubbing and you’re not stepping on the pedal. Ensure your brakes are in top condition for safety and fuel efficiency with a free brake inspection at Les Schwab.

8. Turn Off the EV Comforts When Possible

While comfort controls don’t significantly affect the MPG of gas-powered cars, heated seats, air conditioning, navigation, and stereo systems can reduce battery range in an EV. That’s because the battery power is being used for something other than propelling the vehicle. If you drive an electric car, pre-heat or cool the cabin of the vehicle while you’re charging it.

9. Maintain a Steady Speed

According to the U.S. Department of Energy, using cruise control can minimize speed fluctuations and boost fuel or battery efficiency. Additionally, driving at a consistent speed, ideally between 55 and 65 MPH (when legal), can improve fuel efficiency and range.

10. Use Eco Mode

Most modern vehicles include an eco-driving mode that optimizes acceleration and engine performance for fuel efficiency and a boost in range. By using your vehicle’s eco mode, the computer in your car or truck will limit your acceleration to help you save fuel and battery life.

11. Lighten Your Load

Excess weight can decrease fuel efficiency and range. Removing unneeded items from your car or truck can increase your MPG and battery life. For every 100 pounds you remove, you’ll earn back up to 1% of your miles per gallon, according to Consumer Reports.

12. Limit Roof Racks and Cargo Toppers

Ski racks, overlanding gear, and even cargo toppers create drag, especially at highway speeds, and can limit your MPG and range through air resistance. Some estimates say you could lose up to 25% fuel and battery efficiency at highway speeds. If you’re not using them, remove them.

13. Modifications Impact Your Vehicle’s MPG

Lifting, leveling, and lowering a vehicle is a nice way of personalizing your ride. However, those alterations can, in some situations, impact your overall miles per gallon and range. Other MPG-altering changes can include adjusting the camber and toe of your tire and wheel assembly. Talk with the professionals at Les Schwab about your options.

14. Avoid Excessive Idling

Idling can waste up to half a gallon of fuel per hour, according to the U.S. Department of Energy. It also uses battery power. Unless you’re thawing it out or cooling the inside of your car or truck, don’t leave your vehicle idling for more than a minute. In fact, many state and local governments have idling ordinances and/or idle reduction programs to encourage energy-efficient driving and help reduce fuel consumption and greenhouse gas emissions per vehicle mile. Instead of idling your car to warm it up, start driving gently. This warms up the engine on gas-powered vehicles for added efficiency.

15. Properly Maintain Your Vehicle

Regular maintenance can help achieve peak efficiency. In addition to checking the air pressure in your tires, replace air filters, spark plugs, and oxygen sensors as needed or recommended by your manufacturer.

Les Schwab Has the Tires, Wheels and Services You Need

Stop by your local Les Schwab for free services like air pressure checks and brake inspections. Our professionals will show you how to improve your fuel efficiency and range, whether that’s with a new set of tires, an alignment, or simply showing you how to engage the eco mode on your vehicle. We’re here to help improve your fuel efficiency and get you back on the road safely.

Book Your Appointment Book Your Appointment

Important Notice: The information provided above is of a general nature gathered from a variety of resources deemed reasonably reliable. The operation of your vehicle, or the repair or replacement of your vehicle’s equipment, may be different than for a typical vehicle. Please consult your owner’s manual for specific warnings, notices, and other advice relative to the subjects addressed herein.

Opens warranty information dialog with language options